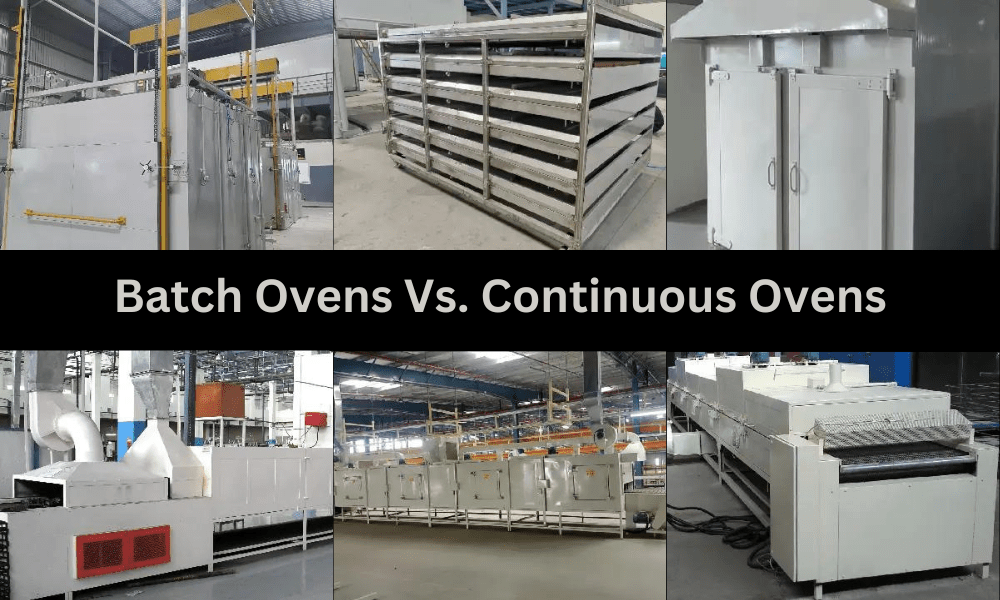

The choice between batch ovens and continuous ovens for your facility depends on various factors, including your production requirements, product characteristics, and budget constraints. Let’s explore the key differences and considerations for each type:

Batch Ovens

Operation: Batch ovens process a specific quantity of products at a time. Once one batch is completed, the oven is emptied, and a new batch is loaded. This process is repeated for each batch.

Flexibility: Batch ovens are generally more flexible, allowing you to change products or recipes between batches without extensive reconfiguration.

Energy Efficiency: They can be more energy-efficient for low production volumes since the oven is only in use when a batch is being processed.

Suitable Products: Batch ovens are ideal for small to medium-sized production runs and products that require different processing conditions.

Continuous Ovens

Operation: Continuous ovens are designed for a continuous flow of products through the oven, rather than processing them in batches. Products enter one end and exit the other in a continuous manner.

Throughput: Continuous ovens are generally more suitable for high-volume production as they offer a steady and uninterrupted process flow.

Energy Efficiency: In terms of energy efficiency, continuous ovens can be more economical for high-volume production due to their continuous operation, which reduces downtime and startup/shutdown energy costs.

Suitable Products: Continuous ovens are better suited for products that have consistent processing requirements and can withstand continuous movement.

Considerations when choosing between the two types:

- Production Volume: If your facility deals with high production volumes and requires a constant, uninterrupted flow of products, continuous ovens might be more appropriate. For lower production volumes or varied product types, batch ovens may be a better fit.

- Energy Efficiency: If energy efficiency is a critical concern and you have a high production volume, continuous ovens might be more economical in the long run. However, if your facility operates in batches and has downtime between runs, batch ovens can be more energy-efficient.

- Product Characteristics: Consider the characteristics of your products. If they require different processing conditions or if you frequently change product types, batch ovens offer greater flexibility. For products that can handle continuous processing without compromising quality, continuous ovens may be the better choice.

- Capital Investment: The cost of installing continuous ovens can be higher than batch ovens due to their continuous flow design and associated conveyor systems. Consider your budget and return on investment when making the decision.

In conclusion, the choice between batch ovens and continuous ovens depends on your specific production requirements, energy considerations, product characteristics, and budget. It’s essential to evaluate your facility’s needs and consult with oven manufacturers or experts to determine the best fit for your business.

Batch Oven – At RDR Taichi, we provide you with the best in predesigned and custom engineered batch process ovens. Each unit is designed to meet your specifications, ensuring highly reliable operation and performance for decades to come.

We provide you Batch Ovens with multiple options like, with Trays & Shelves, with Trolley, with Motorised Vertical Doors having multiple leaf options etc.