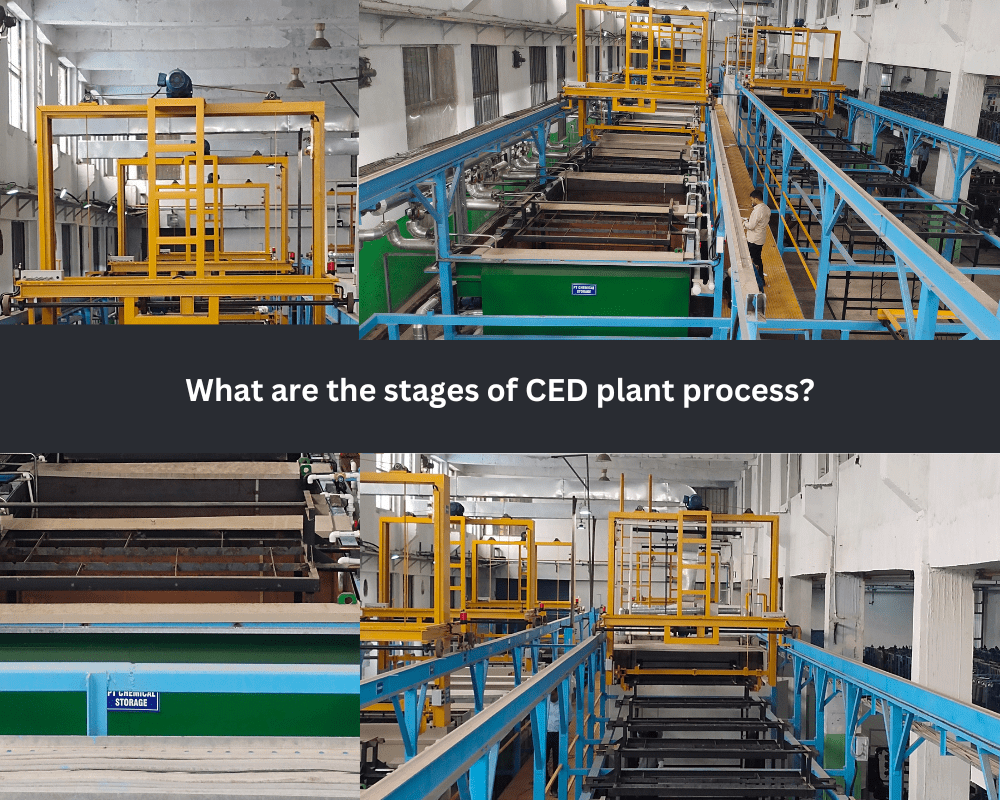

CED (Cathodic Electrodeposition) coating is a highly effective and widely used method for applying a protective and decorative finish to various metal substrates. It is commonly used in industries such as automotive manufacturing, aerospace, appliances, and more. The CED coating process involves several stages, including pre-treatment, electrodeposition, and post-treatment. Here’s an overview of the CED coating plants process:

Pre-Treatment: The first step in the CED coating process is preparing the metal substrate for coating. This involves cleaning and pre-treating the surface to ensure proper adhesion and corrosion resistance. The pre-treatment process typically includes the following steps:

- Cleaning: The metal substrate is cleaned to remove dirt, oil, rust, and other contaminants. This can be done using chemical cleaning agents, alkaline cleaners, or high-pressure water washing.

- Surface Etching: In some cases, the metal surface may be etched to improve adhesion. Etching is usually done using acid-based solutions.

- Conversion Coating: A conversion coating, often based on zinc or iron phosphate, is applied to the metal surface. This coating helps improve corrosion resistance and adhesion of the CED coating.

- Rinsing: After each pre-treatment step, the substrate is thoroughly rinsed to remove any residual chemicals.

Electrodeposition: The core of the CED coating process is the electrodeposition step. In this stage, the metal substrate is immersed in a specially formulated CED coating bath, which consists of water-based paint with pigments, resins, and other additives. The key components of the electrodeposition process include:

- Electrocoat Bath: The bath contains the CED coating material, which is typically a mixture of epoxy or acrylic resins and water.

- Electrodes: An anode and a cathode are placed in the bath. The metal substrate to be coated acts as the cathode, while the anode is usually made of an inert material like stainless steel.

- Electrical Current: An electrical voltage is applied between the anode and cathode, causing the CED coating material to migrate and deposit onto the metal substrate. The positively charged paint particles are attracted to the negatively charged substrate.

- Film Build: The thickness of the CED coating layer can be controlled by adjusting the electrical current and immersion time. Thicker coatings are achieved by increasing the deposition time.

Post-Treatment: After the electrodeposition process, the coated substrate is subjected to post-treatment processes to improve the coating’s properties. These processes may include:

- Curing: The coated parts are heated in an oven to cure the CED coating, allowing it to cross-link and harden.

- Quality Control: Coated parts undergo various quality control tests to ensure thickness, adhesion, corrosion resistance, and appearance meet the desired specifications.

- Final Inspection: Inspectors check for any defects and perform visual inspections to ensure the coating is uniform and free of blemishes.

- Packaging and Shipping: After passing quality control, the coated parts are packaged and prepared for shipment to the customer or the next stage of manufacturing.

CED coating plants are highly automated and use precise control systems to maintain consistent coating quality. The process can be customized to meet specific performance and appearance requirements for different industries and applications.