A varnish coating machine for motor stators works by applying a protective layer of varnish onto the stator windings to insulate and protect them. The exact process can vary based on the specific design of the machine and the desired coating quality, but here’s a general overview of how the machine typically works:

- Preparation of Stators: The motor stators are prepared for coating. This might involve cleaning, degreasing, and ensuring the surfaces are free from contaminants that could affect the adhesion of the varnish.

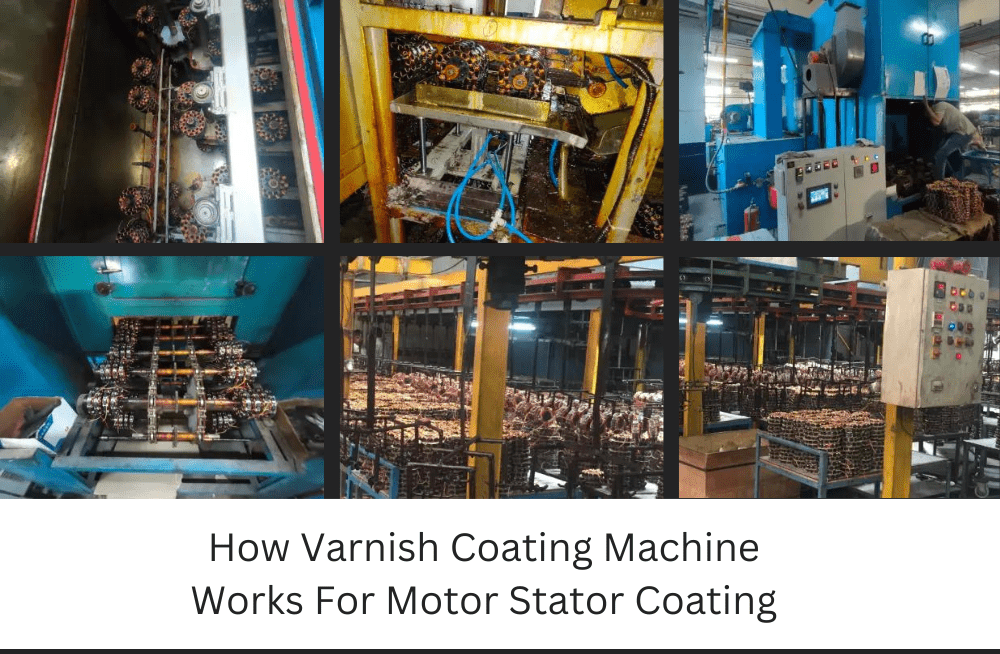

- Loading: The stators are loaded onto the machine’s conveyor system or other loading mechanism. This can be done manually or through an automated process, depending on the machine’s design.

- Coating Application: Dipping Method: In a dipping method, the stators are submerged into a vat of varnish. They are then slowly lifted out, allowing excess varnish to drip off. The varnish adheres to the stator windings as they are withdrawn from the vat.

- Coating Control: The machine’s control system ensures that the varnish is applied at the desired thickness and coverage. This can involve regulating the speed of the conveyor, controlling the spraying/dipping mechanism, and monitoring the varnish viscosity.

- Drying or Curing: Heat: Some machines incorporate heat sources to accelerate the drying or curing process. The stators might be moved through a heated chamber or subjected to infrared lamps. Airflow: Airflow can be used to facilitate the drying process by promoting solvent evaporation. This can be achieved through fans or other ventilation systems.

- Quality Control and Inspection: Some machines include sensors or cameras to inspect the coated stators for uniformity, thickness, and defects. Any stators that don’t meet the required quality standards can be flagged for further inspection or rework.

- Cooling (if needed): After the varnish is dried or cured, a cooling process might be employed to bring the stators to a suitable temperature for further handling or testing.

- Unloading: Once the varnish is properly applied and cured, the stators are unloaded from the machine. This can be done manually or through an automated process.

- Post-Coating Processes: Depending on the manufacturer’s requirements, the coated stators might undergo additional testing, inspection, and assembly processes.

It’s important to note that the exact workings of a varnish coating machine can vary based on factors such as the type of varnish used, the production volume, the desired quality of coating, and the specific design features of the machine. The primary goal is to ensure consistent, reliable, and high-quality varnish application to protect the motor stator windings effectively.

Contact our sales team for more information. Take advantage of our many years of experience.

Call Us: (+91) 7701931695

Mail Us: info@rdrtc.com

Visit: https://www.rdrtc.com/