The CED (Cathodic Electrodeposition) Coating process is a method used for applying protective and decorative coatings to various objects or components. It involves the electrochemical deposition of a paint or coating material onto a conductive surface using an electrical current. The CED process provides a uniform and durable coating with excellent corrosion resistance.

Automotive Industry:

In the automotive industry, CED coatings are widely used for corrosion protection and enhancing the aesthetic appearance of vehicle parts. Components such as car bodies, chassis, suspension parts, and various metal parts undergo the CED process. The uniform coating thickness and excellent adhesion provided by CED coatings help protect against rust, weathering, and other environmental factors, ensuring the longevity and durability of automotive parts.

Appliances Industry:

CED coatings find applications in the appliances industry for coating various metal parts of appliances like refrigerators, washing machines, dishwashers, ovens, and more. The coatings protect against corrosion, moisture, and chemical exposure, ensuring the longevity and visual appeal of these appliances.

Furniture Industry:

In the furniture industry, CED coatings are commonly used for coating metal furniture components, such as chair frames, table legs, and other metal structural parts. The coatings provide a smooth and durable finish, protecting against corrosion, scratches, and wear-and-tear. CED coatings also offer the flexibility to achieve different colors and aesthetics, enhancing the overall appearance of furniture pieces.

General Manufacturing:

The CED process is utilized in various general manufacturing applications where metal parts require protection against corrosion, as well as improved visual appeal. It finds applications in industries such as industrial machinery, electronics, metal fabrications, agricultural equipment, and more. CED coatings help extend the lifespan of components and improve their overall quality and reliability.

The CED process offers several advantages to these industries. It provides a uniform coating thickness, even on complex-shaped objects, ensuring consistent protection. The coatings adhere well to the surface, providing excellent corrosion resistance and durability. Additionally, the CED process is environmentally friendly, as it typically uses water-based coatings with lower VOC emissions compared to traditional solvent-based coatings.

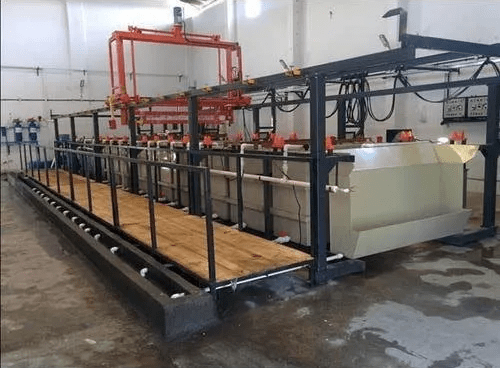

We are Manufacturer, Supplier and Exporter of CED Plants and our setup is situated in Gurgaon, Haryana, India. Cathodic Electro-deposition ( CED ) is Water Based primer coating & mostly used in automotive paint shop.